Blast resistant glass (sometimes called explosion proof glass) is made up of materials that allow it to have the strength and plasticity to absorb much of the pressure of an explosion.

In a blast resistant building, it’s just as crucial for doors and windows (which may contain glass) to be made of blast resistant materials as it is for the rest of the structure.

How Does Blast Resistant Glass Work?

When subjected to explosions, blast resistant glass is flexible and remains in its frame by absorbing the force of the blast. The goal is to prevent shattering, holes, and punctures to the glass, keeping the glass pane intact even after an explosion. Blast resistant glass has a rating system, depending on how much blast force it can absorb.

To withstand the force of an explosion, blast resistant glass is typically:

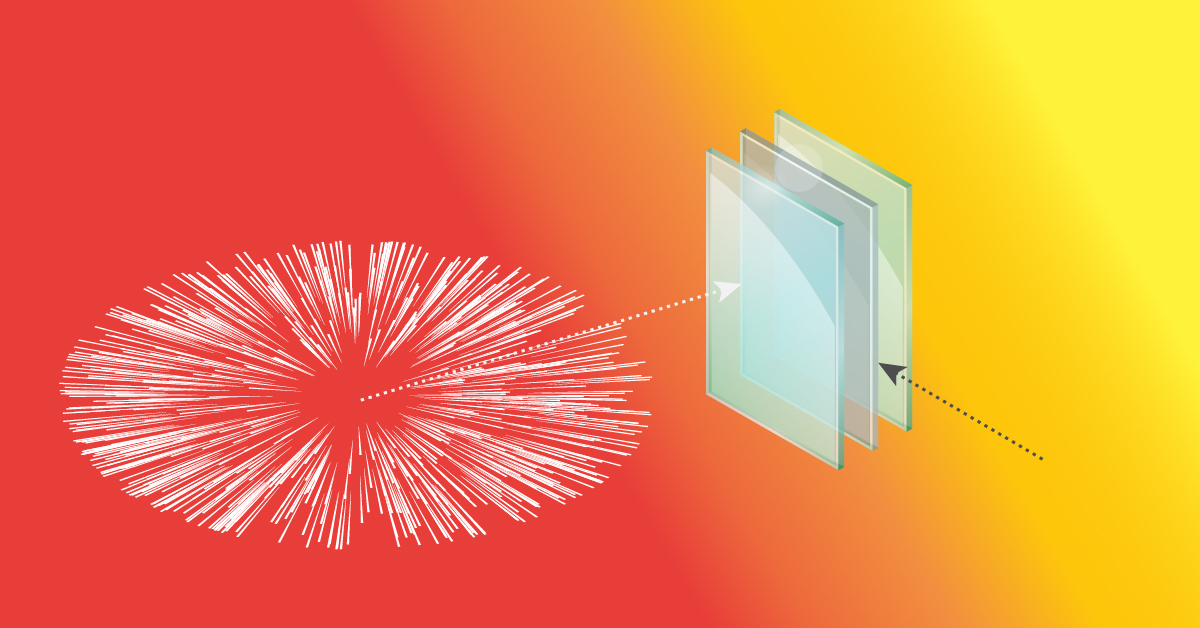

- Made with a high-performance polymer interlayer (typically polyvinyl butyral (PVB), a tough plastic resin used between two panes to bond them together)

- Reinforced with a glazing system or laminate layer to hold glass fragments in place

- Designed to stay in its frame using specialized anchoring solutions

All blast resistant glass undergoes explosion testing to assess the amount of damage and glass fragments produced under different amounts of pressure. This provides the information necessary to meet the criteria of varying building standards.

Blast resistant glass specifications

Glass is given a blast-resistance classification indicating its ability to withstand an explosion without shattering. However, there are many other technical specifications and testing methods that apply to blast resistant glass, depending on its purpose and the location of its use. These include:

- GSA-TS01:2003 – The U.S. General Service Administration’s “Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings” (also adopted in the U.K.)

- EN 13541 – The E.U.’s specifications of test methods, performance requirements, and classification for explosion pressure resistant glazing for use in buildings.

- ISO 16933:2007 – The International Organization for Standardization’s guidelines on “Glass in Building - Explosion-Resistant Security Glazing - Test & Classification for Arena Air-Blast Loading”

The U.S. Department of State Bureau of Overseas Building Operations (OBO), the Department of Defense, and the Department of Veterans Affairs also have criteria for the use of blast resistant glass in their facilities.

In cases where blast resistant buildings include windows, these need to be engineered to match or exceed the overall building’s hazard rating. A building is only as strong as its weakest link. Therefore, a building with a strength rating of 8 psi with a 5 psi window will be rated overall at 5 psi.

When to Use Blast Resistant Glass?

Blast resistant glass is an essential element of buildings where industrial blasts or other types of explosions may occur. It’s most commonly used in doors, windows, and glass panels between rooms.

Glass hasn’t always been a safe building material for blast resistant buildings. Still, recent improvements in design make them safer and allow them to improve the functionality of blast resistant buildings.

Redguard’s blast resistant modular buildings can be customized with windows for customers who need them. Glass can also be used to create internal windows into other rooms when processes need to be monitored, or when personnel need to interact.

Industries That Utilize Blast Resistant Glass

Blast resistant glass is used in buildings with the potential for explosions, whether accidental or intentional. While government buildings and banks use this glass to protect people in the vicinity in the event of a deliberate attack, it’s also commonly used in buildings on job sites where industrial explosions may occur.

Other industries that use blast resistant glass include:

- Sports stadiums

- Large arenas

- Laboratories

- Military installations

- Renewable energy

- Cannabis dispensaries

- Pharmacies

- Petrochemical Facilities

These facilities are prone to accidental explosions, theft, or terrorist attacks.

Does the Glass Remain Intact When an Explosion Occurs?

While the protective glass may still break, ideally, blast resistant glass does not spall, producing shards of glass that break away and become dangerous projectiles that could harm people and property on the site.

Blast resistant glass is designed to mitigate the dangers of flying glass shards during an explosion. Glass will crack following an explosion, but the laminate coating is designed to hold the pieces together and keep them in the frame.

Improving Blast Resistant Glass to Save Lives

The Pentagon’s report on the 1996 Khobar Towers bombing in Saudi Arabia found that of the 19 fatalities, 12 had injuries caused by glass shards that were so severe they could have caused death without any other trauma.

Researchers are making strides to create even more durable blast resistant glass with pure polymer layers to reinforce glass fibers. This is just one of the many ways construction is improving to help save lives.

RedGuard Sales & Marketing

The RedGuard sales and marketing team curates and writes on a variety of topics regarding blast-resistance and modular buildings. To inquire about any of the topics you read about on our blog, connect with us.