Safety & Regulations | Blast Resistant Buildings | Hazard Protection

Toxic Gas Protection in Specialized Modular Buildings

In the world of high-risk workplaces, such as petrochemical facilities, one thing takes precedence above all else: the safety and well-being of the individuals within. The focus here is on hazardous gases—these are the invisible threats that can have severe health consequences when breathed in. We’ll explore the layers of protection in RedGuard's specialized modular buildings that keep workers safe.

The Dangers of Toxic Gas

Hazardous gases are categorized based on their toxicity levels, often quantified by their LC50—the concentration at which 50% of test animals die during exposure. The National Fire Protection Association (NFPA) classifies these gases into four categories, with Class 4 representing the most highly-toxic, Class 3 for dangerous toxic gases, and Class 2 for moderately-toxic gases, and Class 1 for least-toxic gases. However, it’s important to note that the Global Harmonized System (GHS) reverses this classification with Class 4 being least-toxic. Understanding these categories is crucial for assessing the potential dangers of hazardous gases and implementing appropriate safety measures.

One critical concern is the presence of hazardous gases in confined spaces, particularly in refineries during inspections and maintenance. A permit to work is mandatory to ensure safety, with gas detection being a crucial step before entry. Portable gas detection equipment is used to identify residual toxic gases, such as hydrogen sulfide or elevated nitrogen levels, some of which can be invisible and odorless, creating an extremely hazardous atmosphere.

Gas detection systems are indispensable for safeguarding workers by serving as early warning systems. For example, in industries like oil and gas, deadly gases like petroleum gases (benzene, butane, methane), hydrogen sulfide (H2S), diesel exhaust, mercury vapor, and flammable gases pose significant threats. Mitigating these risks involves a range of measures, including the use of self-contained breathing apparatus (SCBA), classified HVAC systems that can provide positive pressure and purging, monitoring equipment, engineering controls, employee training, low emission engines, exhaust treatment devices, risk assessments, and comprehensive safety programs. Proactive measures are essential to ensure both worker safety and environmental preservation.

How to Know What Level of Protection Your Facility Requires

When you partner with RedGuard for your specialized modular building, our experts will work closely with you to identify and implement tailored toxic gas protection measures. With RedGuard as your partner, you can have confidence that our solutions are designed to keep your facility and its occupants safe from potential toxic gas hazards.

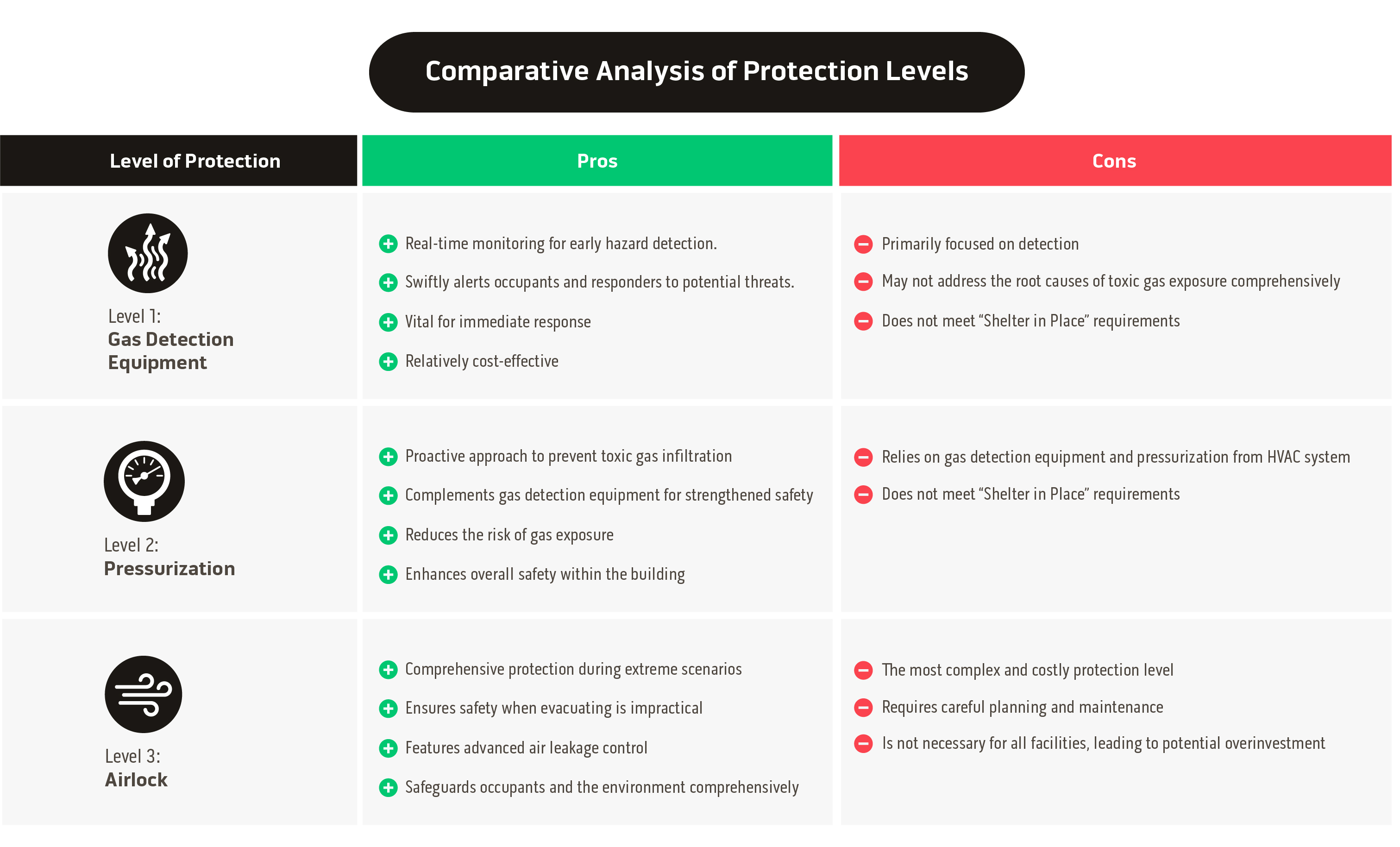

Level 1: Gas Detection Equipment

Gas detection equipment plays a pivotal role in identifying the presence of toxic gases within a specialized modular building. Gas sensors are the frontline defense, providing real-time monitoring to promptly alert occupants and responders to potential hazards. Examples of common toxic gases detected include hydrogen sulfide (H2S), methane, and others relevant to specific industries. However, it's important to recognize that relying solely on gas detection, while vital, may have limitations in terms of addressing the root causes of toxic gas exposure.

Level 2: Pressurization for Enhanced Safety

The second level of protection involves pressurization systems designed to maintain positive pressure within the specialized modular building. These systems work in tandem with gas detection equipment to prevent the infiltration of toxic gases. The "fresh air stack" plays a critical role in this process by continually introducing clean, outside air to maintain positive pressure. This positive pressure environment helps create a barrier against the ingress of hazardous gases, bolstering safety measures within the structure.

Level 3: Airlock for "Shelter in Place" Requirements

At the highest level of protection, specialized modular buildings incorporate an airlock system to meet "shelter in place" requirements during extreme situations with potential toxic releases. Understanding scenarios that necessitate an airlock system is crucial, as this protection level ensures safety when evacuating might not be feasible. The airlock system consists of components such as substantial pressurization, sealants, and vestibules, all working together to create a controlled environment that prevents the entry of toxic gases. The concept of "shelter in place" becomes a lifeline in such scenarios, emphasizing the importance of advanced air leakage control.

In some cases, a combination of these levels may offer the most balanced approach to toxic gas protection.

Protect Your Facility with Comprehensive Toxic Gas Protection

In hazardous industries, prioritizing safety is pivotal. Comprehensive gas detection and safety measures help prevent accidents and protect both workers and the environment. It's crucial to choose a protection level that complies with regulations and prioritizes worker safety. Whether you opt for gas detection equipment, pressurization systems, airlock configurations, or a combination, always keep in mind that the safety of your occupants is the top priority.

Specialized modular buildings demand tailored solutions to address specific safety concerns, and at RedGuard, we take pride in offering just that. Recognizing that one size does not fit all, we understand the importance of customization. That's why we invite you to delve deeper into our offerings by exploring our comprehensive guide below.

RedGuard Sales & Marketing

The RedGuard sales and marketing team curates and writes on a variety of topics regarding blast-resistance and modular buildings. To inquire about any of the topics you read about on our blog, connect with us.