Enhancing safety in O&G: The imperative of applied knowledge

This article was originally published in the September/October 2023 issue of BIC Magazine. It was written by RedGuard's Sales Support Specialist, Lorna Geist.

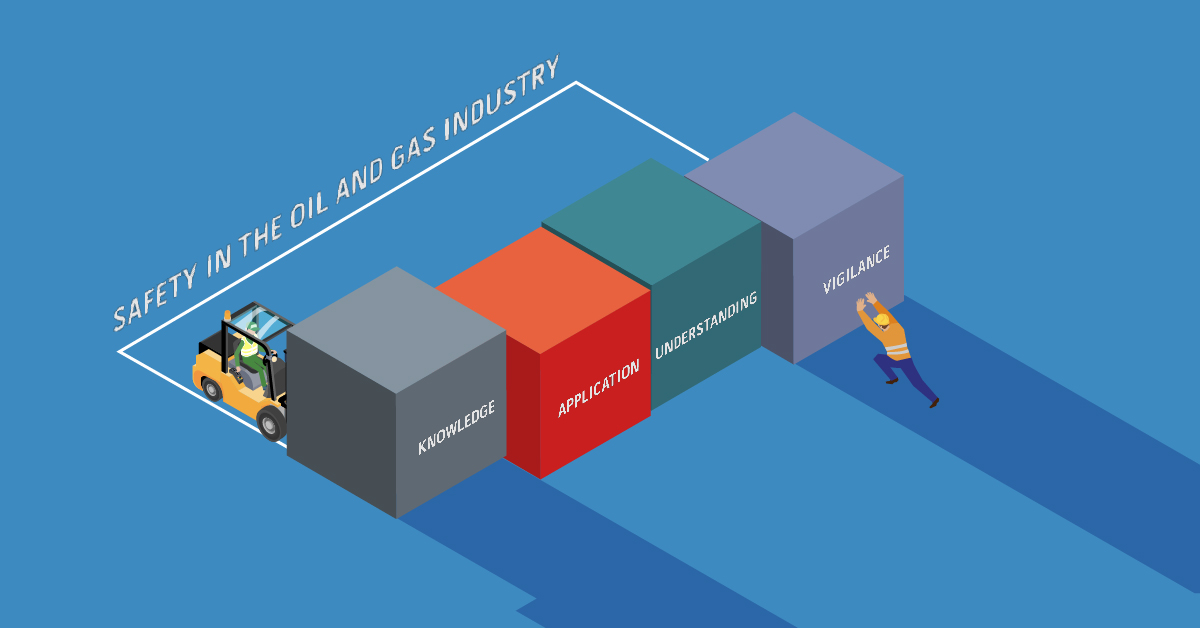

In the O&G industry, knowledge is abundant, with reports and guidelines from esteemed organizations at our fingertips. However, knowledge alone does not guarantee safety — it’s the application of that knowledge that truly makes a difference.

In the same manner that complacency can affect our safety outcomes, it also affects fact-seeking and comprehension. While it is relatively easy to find information in a sea of publications, how does one discern context, timeliness, and reliability of knowledge? When several writings are referenced, how do you know which ones are pioneering and which are outdated?

Skimming articles and overlooking crucial details can lead to misunderstandings and poor decision-making. To illustrate this, let's consider the evolution of blast-resistant building design guidelines over the years.

Important information, such as the article "Design of Blast-Resistant Buildings in Petrochemical Facilities" by the American Society of Chemical Engineers (ASCE), and Recommended Practice 752 and 753 from API, have undergone revisions and updates, reflecting advancements in technology and best practices.

The ASCE article has been available since 1997, and an updated second edition was released in 2010. Similarly, API RP 752 was initially written in 1995 and has undergone revisions in 2003 and 2009.

API RP 752 addressed permanent structures since no companies were building blast-resistant buildings for temporary usage. API RP 753, a guideline for portable and temporary buildings, was published in June 2007 and updated in 2020. It now overrides anything shown in RP 752. However, if one were to read only the early ASCE piece, there are some bold statements in that publication about the type of materials that are best for blast-resistant buildings. Failing to stay updated with the latest information may result in subpar design choices, potentially compromising safety.

Skimming also often results in a lack of understanding of unfamiliar words or concepts. This is understandable when you consider the long reports focusing on the structural aspects of design and evaluation for blast-resistant buildings. However, understanding unfamiliar terms and concepts is vital for practical application. By embracing applied knowledge, we empower ourselves to make informed decisions that enhance safety in the O&G industry.

It's easy to study reliable sources of information yet overlook the purpose of the writing. Turning again to the ASCE document, we can ascertain the historical evolution of this writing. Originally, blast-design technology for blast-resistant buildings consisted of 'equivalent static loads' and 'conventional static design methods.' It then evolved to consider dynamic characteristics and ductility of structural components and took on blast loading based on trinitrotoluene (TNT) equivalents. Today, it encapsulates methods involving more dynamic models to analyze building structures. By knowing this progression, one can apply the knowledge that if the blast-resistant manufacturer is evaluating its building design by older methods alone and not incorporating the newer calculations, the building may not be the best fit for your hazard needs.

Knowledge serves as a foundation, but it is through applied knowledge that we unlock true safety potential. Applied knowledge is turning to those who study blasts, threat mitigation, and blast-resistant buildings and who have dedicated their professional lives to keeping you and your employees safe. Complacency is not an option.

In his 1993 book Lessons from Disaster: How Organizations Have No Memory and Accidents Recur, Trevor Kletz states, "It might seem to an outsider that industrial accidents occur because we do not know how to prevent them. In fact, they occur because we do not use the knowledge that is available."

RedGuard has been designing and manufacturing blast-resistant buildings since 2005 and has worked with some of the best third-party blast engineers in the industry.

For more information, visit RedGuard online, or call (855) 733-4827.

Lorna Geist

Lorna has been with RedGuard since 2012 and is a sales specialist. Her specialty is generating quotes for all the creative ways our customers use LeaseFleet buildings. She is also a member of the LANGE culture committee, which focuses on keeping employees from RedGuard and all LANGE companies focused on our core values.