Best Practices | Safety and Regulations | Hazard Protection Protocols

Where Blast Resistant Buildings Fall in the Hierarchy of Controls

The best way for companies to ensure worker safety and prevent accidents is to identify and control hazards on worksites.

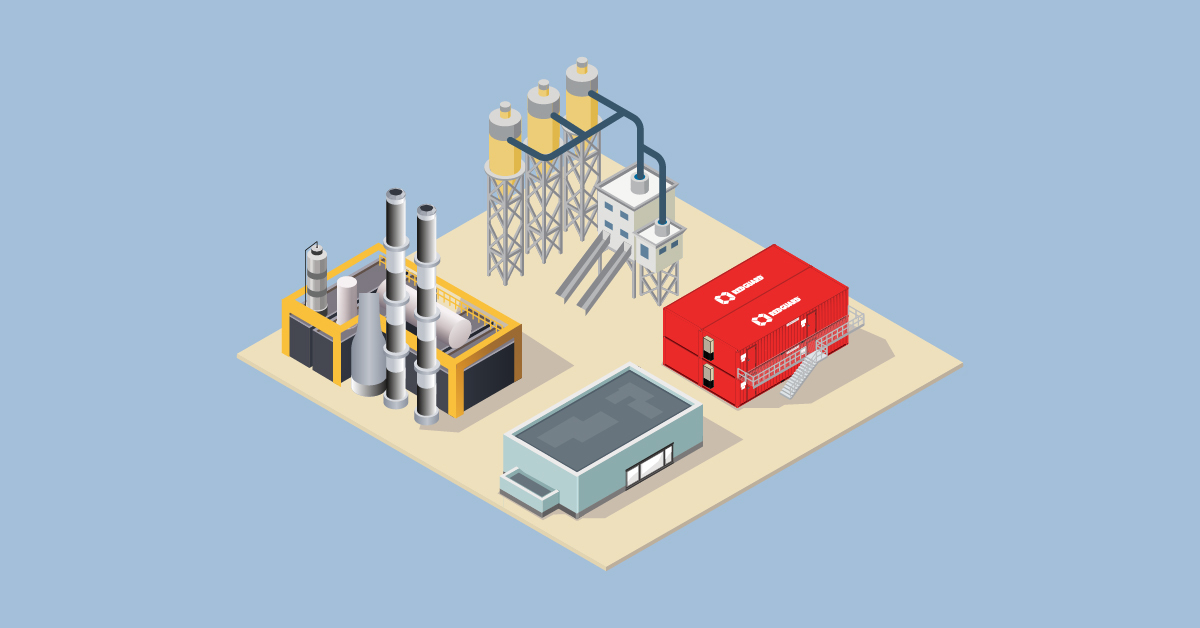

However, not all accidents can be predicted and prevented. In those cases, the best employers put in place protective mechanisms to keep people safe when the worst occurs. For example, to prevent injuries from worksite explosions, some hazardous sites have their team working in blast resistant buildings to avoid injuries and flying debris if a blast were to occur.

Below, we’ll examine how a system called the hierarchy of controls helps employers develop comprehensive accident prevention programs to reduce the frequency of both accidents and injuries.

What is the Hierarchy of Controls?

The hierarchy of controls is a set of actions designed to remove or reduce hazards, injuries, and exposures.

At the top of the hierarchy are the most effective actions. These actions protect workers by eliminating risks altogether. As you move down the hierarchy, you accumulate various ways of controlling potentially dangerous situations that may not be entirely preventable. At the bottom of the hierarchy are the last lines of defense a company should provide for people who work on high-risk worksites. Most employers use multiple layers of strategies rather than just choosing one for optimal protection.

The hierarchy of controls prioritizes mitigation strategies as follows:

- Elimination

- Substitution

- Engineering controls

- Administrative controls

- Personal protective equipment (PPE)

The hierarchy of controls is relevant to all worksites; however it is paramount in high risk industries, such as petrochemical plants, nuclear power, oil and gas facilities, and construction sites.

For example, safety managers at a chemical plant would first check to see if they could eliminate the use of a hazardous chemical. If this were impossible, they would then move down the hierarchy by trying to use an alternative, building better containment structures, updating operating procedures and training, and having suitable respirators on site.

OSHA mandates administrative controls and PPE to ensure that workers are protected in unforeseen situations that could be catastrophic otherwise.

Elimination

In the petrochemical industry, on-site hazards may include equipment malfunctions, corrosion, untrained workers, and even lightning strikes. These can result in anything from spills and collapses to fires and explosions. Because chemicals are typically highly combustible, they present an even more significant hazard.

The first step in a hazard protection plan is to try and eliminate the use of dangerous chemicals. By removing the source of the threat, you prevent any injuries that might result from a malfunction or accident. However, eliminating hazardous chemicals from petrochemical plants is not always feasible due to the nature of the process.

In some cases, safety managers may be able to limit use, but when elimination is not an option, they must look to the next step in the hierarchy of controls: substitution.

Substitution

Substitution requires a plant or safety manager to explore whether or not they might replace the hazardous chemical with a less dangerous alternative. New methods of manufacturing or chemical substitutes that are less combustible may make this possible in ways that were not available 20 years ago.

While elimination and substitution are the most effective controls, in some cases, managers at facilities must move down the hierarchy of controls and use as many relevant alternatives as possible.

Engineering Controls

Engineering controls can typically be employed on most worksites but often require significant upgrades. Still, they’re worthwhile if they can save lives.

Engineering controls may prevent hazards close to the source or provide workers with a means of separating themselves from the danger. These controls can include deploying technology to detect and/or capture chemical leaks, the installation of ventilation to prevent combustion, timely repairs to infrastructure, or protecting fragile equipment with the use of blast resistant buildings.

Even the best safety mechanisms may fail during catastrophic conditions, such as weather events. Therefore, engineering controls that isolate people from the hazard are a great way of committing to worker safety.

RedGuard's safety-tested blast resistant buildings have proven that they can protect workers from heat, fire, shrapnel, and other dangers in the event of an explosion.

Administrative Controls

Administrative controls change how people work. They are usually mandatory safety mechanisms employers must provide to their workers. By the time we get down to this level in the hierarchy of controls, worksite safety programs involve several of these often-mandatory strategies.

Examples of administrative controls in a petrochemical plant may include:

- Developing safety policies around certain chemicals and equipment

- Ensuring workers are trained on these protocols

- Implementing decontamination procedures

- Installing early warning systems

- Restricting access to dangerous parts of the worksite to only trained employees

- Regular equipment inspection and maintenance

- Adequate signage and alarm systems

- Health monitoring

Personal Protective Equipment (PPE)

Regardless of the other controls put in place, employers typically provide PPE as a last line of defense or to augment other safety protocols. Blast resistant buildings are helpful again in this final control since they act as a barrier between workers and on-site hazards.

PPE cannot address the hazards themselves. Instead, they are designed to reduce exposure. Examples include:

- Respiratory masks

- Eye protection and ear plugs

- Helmets and fire-retardant clothing

It's essential to remember that using PPE can limit the damage from chemical spills, but damage to people and property can still occur. That's why it shouldn't be the sole control mechanism.

Companies should start at the top of the hierarchy and implement as many controls as possible on their way down.

Blast Resistant Buildings in the Hierarchy of Controls

Blast resistant buildings are applicable at multiple places within the hierarchy of controls but fit firmly within the engineering level (and the proper training to use them is an administrative control). That's why these buildings are an integral part of a worksite’s safety plan.

If your worksite is performing a:

- Facility Siting Study

- Process Hazard Analysis

- Process Safety Management (PSM) Audit or

- Quantitative Risk Assessment (QRA)

...now is the time to talk to a member of the RedGuard team about including a blast resistant building in your safety plan. As blast resistant industry leaders, RedGuard can help you keep your people safe.

RedGuard Sales & Marketing

The RedGuard sales and marketing team curates and writes on a variety of topics regarding blast-resistance and modular buildings. To inquire about any of the topics you read about on our blog, connect with us.