Articles | Design & Engineering

Why staging matters with blast-resistant buildings

This article, How to Stage a Blast Resistant Building, was originally published on our blog in its entirety in October 2021. This version was shortened for publication in the March/April 2022 issue of BIC magazine.

Suppose you've researched different kinds of blast-resistant structures, like steel blast-resistant buildings, modular concrete blast-resistant buildings, or even blast-resistant tents or air shelters.

You know that there is a lot of conflicting information about why you should buy one type over another. Since the beginning, RedGuard has long been in the blast-resistant building design business and done its fair share of testing, continuously upgrading and working on new methods of keeping occupants of hazardous areas safe.

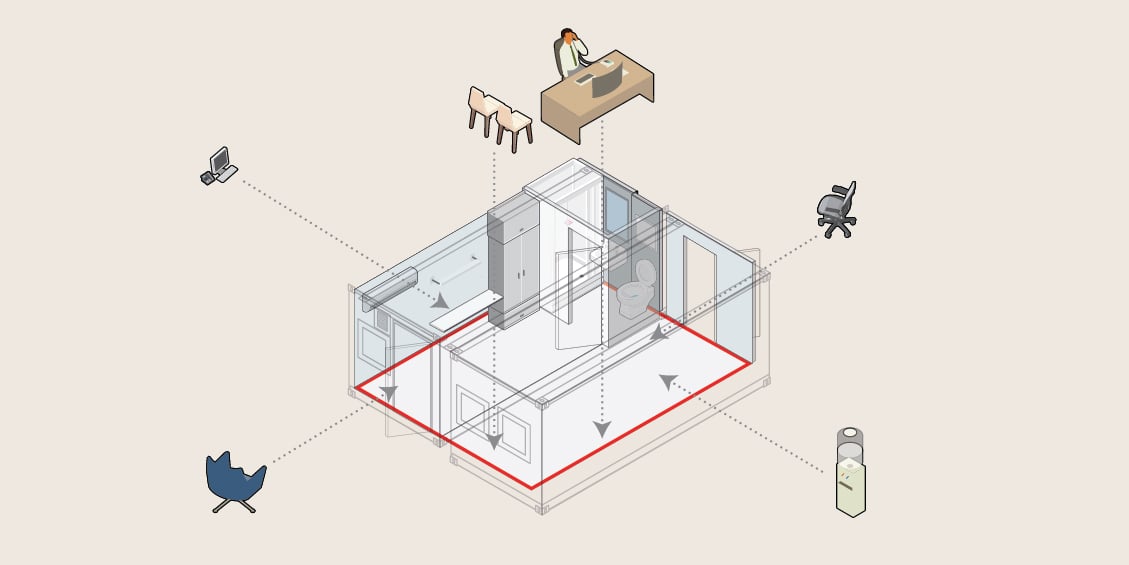

It's important to remember that with different types of buildings, there are many differences in how a building may be staged on the inside. Believe it or not, the way you arrange the things on the inside makes a difference.

Additionally, proper blast design doesn't stop with the building structure. All non-structural items should be examined and scrutinized when manufacturing a life-saving product.

A brief discussion of flex, or dynamic load transfer

One of the protections that steel offers is its flexibility. When impacted by a blast wave, a steel structure will bend slightly rather than break apart. One of the keys to RedGuard's design is the ability to allow for some dynamic structural movement, while limiting total structural deformation. This is a key differentiator of RedGuard among other steel blast-resistant building designs.

When it comes to a modular steel blast-resistant building like those available at RedGuard, there are some specific pointers about properly staging the building to accommodate flexibility.

Because of the flex that could occur if a blast wave impacts a steel building, experts at RedGuard recommend that if large items are added to the building such as desks or other furniture, they are placed a minimum of two inches from the wall. This space allows the structure a minimal area to flex, thus absorbing the blast wave and avoiding the movement of furniture and large items.

To attach items to a wall, they must be attached directly to a structural member, not to the substrate using a fastener with a high thread count per inch. The fastener should also be sized for the weight or size of the item being installed. "Anchored items" usually refers to cabinets, shelves, countertops or other large fixtures.

For each anchored item added to a blast-resistant module, occupants must consider what would happen if it were to dislodge. It's important to note that if you have hanging cabinets in your blast-resistant building, keeping them closed and fastened (unless you are retrieving something) is essential. A cabinet that is left open could spill out, creating flying debris, or it could become dislodged during a blast. As such, RedGuard doesn't recommend using open shelving or cabinets without latching doors.

Staging, design are key in blast-resistant buildings

When manufacturing a life-saving product, a key point is that proper blast design doesn't stop with the building structure itself. The staging of added items is essential, and all non-structural items should be examined and scrutinized.

Designing a blast-resistant building isn't straightforward. It takes a company with years of experience to meet (or exceed) blast-resistant design and performance standards, while also meeting national and local building codes. It takes the right knowledge and experience to combine specialty engineering with architectural engineering.

Companies that aren't used to navigating the world of code enforcement can easily get tripped up along the way. These stumbles could result in a nonconforming building, additional costs incurred by the customer through change orders and, worst of all, a building that just isn't safe during a blast.

RedGuard has the experience to know how to best incorporate simple items like fire extinguishers, smoke detectors and emergency egress lighting. Importantly, it can also incorporate more complex safety systems such as full fire detection and suppression systems, gas detection, hazardous area electrical components and specialized HVACs.

For more information, visit redguard.com or call (316) 554-9000.

Carreen Gibbons

Carreen Gibbons is the Communications Specialist at RedGuard. With a natural curiosity toward technical subjects and a love of learning new things, she writes content for the SiteBox Storage and RedGuard websites and spends her days learning new things about the industries that the companies serve.